HOWARD BRUSH’S HISTORY

FAMILY OWNED,RENOWNED SINCE 1866…

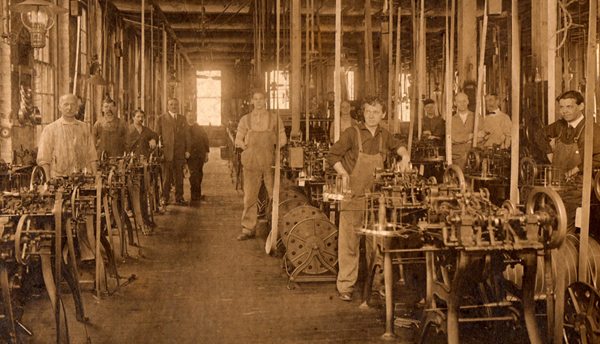

Howard Bros. Manufacturing Company, as we were first called, started in 1866, incorporated in Massachusetts and named for three brothers; Albert H., Charles, and John Howard. At first, their equipment totaled no more than a dozen machines, but gradually Howard Bros. increased, engineering their own machinery and employing hundreds, while suppling a large part of the United States with their superiorly crafted card clothing.

We’re proud to say we’ve steadily grown since, with those same machines running our product now, suppling the world with our industry-leading quality card clothing first developed by our founders and perfected over time with a fineness of skill and technique that can only come from accumulated experience. Our present location is in York, Maine under the operation of Robert and David Bennett.

In the very early days of card clothing manufacturing, much of the process was done by hand. A small, mechanized tool was engineered to produce the wire teeth and these teeth were distributed to women workers who, from home, would punch the hole pattern in the foundation and insert the wire teeth, one by one, into the foundation material creating the finished carding cloth.

From this initial tooth forming machine there have been steady developments in mechanizing the whole process so that, at present time, the entire operation of punching the holes, making the teeth, and setting them in the foundation is all done automatically by one machine. Further, these newer tools are equipped with a stop motion device which pauses the machine immediately if a single tooth is not right or is missing, allowing the engineer to repair and seamlessly restart the process.

Our former President and General Manager, Herbert Midgley, who succeeded Albert H. Howard, was proud of the fact that his father helped develop this engineering advancement, changing the industry completely.

Interestingly, President George Washington during a speaking campaign in Boston, Massachusetts in 1789, made this note of that machine in his diary: “I went to the card manufacturer in Boston where there are machines for executing every part of the work in an expeditious manner, especially in cutting and bending the teeth which is done in one stroke.” We’re still using machinery from the 1800’s today, however, improvements have been made in the different materials necessary for the construction of the card clothing.

In the early days, the wire was ordinary, soft iron, almost nail-like that was crudely formed and unevenly cut. Today, we use a hardened and highly tempered steel wire that is remarkable for its longevity and uniform finish. In addition, wire is offered from very fine to very heavy gauges in all shapes and lengths depending on the application. We’ve also pioneered a precision process of accurately cutting and setting the wire into the foundation, eliminating fluctuations in height or finish.

Equally as important is the foundation material that the wire is set in as it is the backbone of the card clothing itself. The choice and structure of the foundation will give the card clothing its ultimate performance and our specialists at Howard Brush are skilled in choosing the proper variables of wire and foundation to give you your desired result.